Geotextiles – Woven and Nonwoven

FX®-HS Nonwoven (Civil) Geotextiles – Considered multipurpose. This is due to the fact that they can offer immediate and cost-effective solutions for many separation, drainage, erosion control as well as filtration applications.

FX® Slit Film Geotextiles – Offer cost effective solutions for most separation and stabilization applications. They are commonly used in driveways, as well as both paved and unpaved roads.

FX®-MF High-Performance Geotextiles – Were developed to deliver the higher strengths and long-term performance that cannot be achieved by typical woven slit-film fabrics.

Carthage Orange Demarcation Geotextiles – Are essential in projects where a visual warning layer is necessary. Orange fabric is often used to prevent future excavation projects from causing damage, but also serves as a prompt for workers to stop digging.

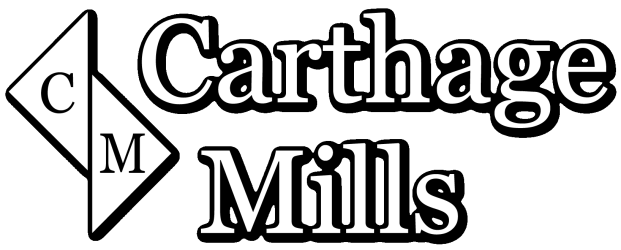

Carthage %™ Open Area Woven Monofilament Geotextiles – Provide long-term solutions for nearly any drainage / filtration application. This product line also has special weave patterns and monofilament yarns that produce a high Percent Open Area (POA).

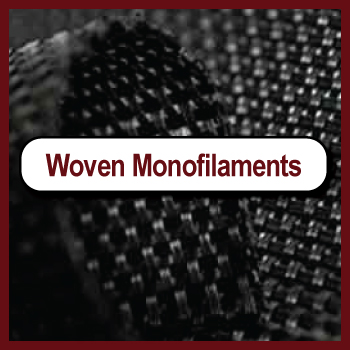

FX®-PET High-Strength Woven Polyester Geotextiles – Deliver the higher ultimate tensile strength properties. They are also resistant to installation damage, as well as offering exceptional creep resistance and soil interaction. This results in higher long-term design strengths (LTDS) per GRI-GT7.

Livestock Mud MatTM – Will separate your cover material from the mud below. This prevents the cover material from intermixing, as well as evenly distributes weight. This prevents ‘ruts’ or ‘depressed areas’ that would negatively impact the health of the livestock.

Geotextiles: Types and Series by Function – This is a chart showing the different series of geotextile fabrics. It also shows what functions they typically serve such as separation, erosion protection, asphalt overlay, and many more.

Carthage FX®-A/O Asphalt Overlay Fabrics – Provide an economic solution to extending the useful life of pavement overlays. They also improve the performance of asphalt road surfacing and resurfacing by up to 50%. They do this by reducing the “causes” of overlay fatigue failure.